|

Transferring Stock - Overview

|   |

Transfers - Stock can be transferred between locations using the Transfer Interface (see below). Any location can request stock from any other location. Any location can push stock out to any other location. All locations can act as suppliers to other locations. In a typical setup each location will see headquarters, and possibly other locations, as the supplier for some or all items in their inventory. It is possible, and likely. that there is a mix between sourcing items internally, i.e. from other locations, and externally, ie from standard suppliers outside the organisation. A stock item can have another location as the preferred supplier and an external supplier as a secondary supplier and visa versa.

Transfers are initiated either at the Requesting location or the Supplying location. At the requesting location requests are explicitly created via the Interlocation Transfer interface (see image balow). In addition the standard purchase ordering system can be used to implicitly create Transfer Requests. Any item ordered via the Purchasing Ordering interface from another location/branch will generate a Transfer Request to that location when the Purchase Order is locked.

Note: just as in the case of locking Purchase Orders directed to external suppliers, once locked a Transfer order should not be reactivated as the supplying location has a copy of the original order at the instant it is locked and may be fulfillling the order. Unlocking and relocking can give rise to anomalies and is only to be carried out when the operator is sure the supplying location has not started processing the Request.

Request Based Transfers - The requesting location initiates the Transfer request (either by starting a standard Transfer Request and adding items to it or locking a standard Purchase Order directed to another location). When the Transfer is locked it is picked up by the Supplying location, stock is allocated and dispatched and received into the requesting locations data using bulk receiving. The bulk receiving process is recorded via the Purchase Ordering interfaces.

Push Based Transfers - The supplying location initiates the transfer of stock without receiving a request. This is typical when head office wants to distribute stock to branch locations without requiring a specific request for it. The receiving location processes the transfer using batch receiving. The receiving process is recorded via the Purchase Ordering interfaces.

Typically Transfer Requests will be a mix of Request and Push.

Cost propagation between Supplier and Requester

The administrator can control how costs and Sell Price are propagated when a transfer is carried out. In the Multi-Location configuration interface (password protected) you can specify that a Supply Location's Costs and/or Sell Price are propagated to the Requester by default. When this option is set for Costs (typically set for HQ only) any time a request is raised for Stock from that location the transfer request will specify that the Supply Locations costs are to overwrite the Requesting locations costs (WAC) when the item is received into that system. The same applies to Sell Price. These 2 flags can be overridden at any time by the Supplier or the Requester up until the time the items are received.

The Sell Price and Cost displayed in Transfers is always taken from the Full Price and WAC at the Supply location. The 2 propagation flags control whether these will overwrite the Requesting locations values when the goods are received. In many cases the initial transfer from HQ could be set to overwrite both the Sell Price and Cost. Subsequent transfers might only overwrite the Cost as the sell price at specific locations may be set locally.

Check for New Push based Transfers - After a Push based transfer has been dispatched by the Supplying Location the Requesting location can update its status by running the Check for New Push based Transfers command. Running this will synchronise the purchase ordering sub-system so that operators can see immediately what stock has been included in the Push Transfer when they view corresponding stock records. This is automatically available for Request based Transfers, just as it is for standard purchase ordered items.

Bulk Receiving - Bulk receiving is available in the Enterprise Version of Bookmine. It allows any Purchase Oder to be bulk received against. Bookmine displays the list of items to be received, with the quantity being received set equal to the quantity ordered. The operator can override the quantity being recieved based on the actual quantities received. The goods are received into the system in batch mode. The process can be run numerous times if the stock arrives in several batches.

Reporting - On screen, interactive Reports display Transfer Requests for specific periods, detailed or summarised by stock item. The reports can be limited to show only requests from this location for stock or transfer where this location is the supplying location. Click the Reports button to display reports.

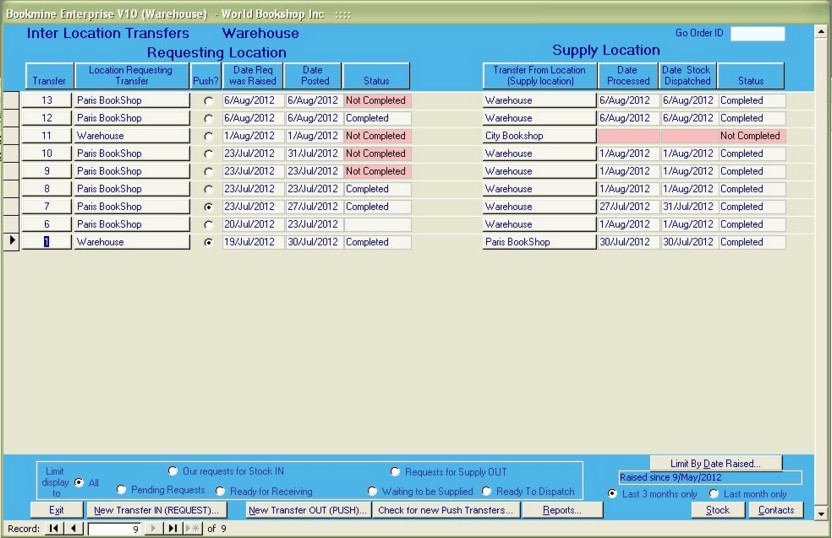

Interlocation Transfer interface

Displays all Transfer Requests for stock from and to this location. New stock is requested using the New Transfer (Request) command, stock can be pushed out to other locations using the New Transfer (Push) command.